Roundtable Takeaways: Food Manufacturing 2.0

On June 18, we hosted an exclusive virtual roundtable for Premium corporate and investor members on food manufacturing efficiency. Hosted by Global Partnerships Director Caroline Keeley, the conversation featured RaboResearch Packaging and Logistics Analyst Xinnan Li, Marble Technologies CEO Chafik Barber, Siembra Head of Business Development Carlos Mancera Portilla and Foodbytes Data Intelligence Analyst Sonia Shekar.

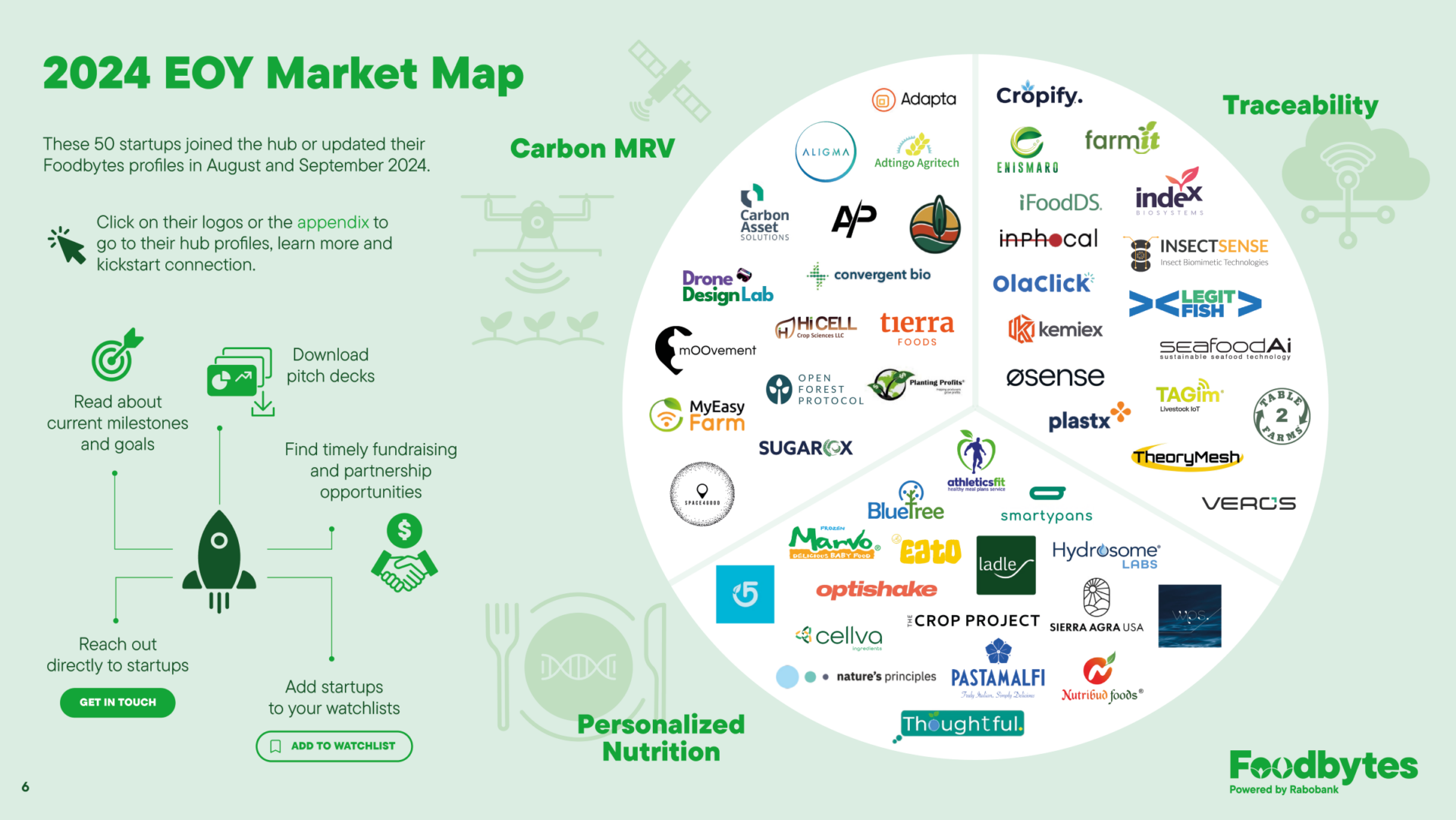

Accompanying our 2024 in-depth Reports, our bi-monthly virtual roundtables feature diverse industry perspectives. In Q1 we focused on Sustainable Inputs, in Q2 Manufacturing Efficiency (key takeaways below!), and in Q3 we’ll explore End-to-End Traceability.

Join the hub today for the opportunity to be invited to our next dynamic discussion.

1. Automation is still in the early stages of commercialization

- Referencing Amara’s Law, Xinnan Li reminded us that “We tend to overestimate AI or technology’s impact in the short term but underestimate its potential in the long-term.”

- Automations and robotics are great at some tasks but not at others. Currently, they can solve for simple tasks such as sorting, but struggle with complex, dexterous tasks such as picking unique products.

- In the near term, AI’s strength as it pertains to midstream food and ag lies in inventory management and demand forecasting, while humans are still necessary for QA (quality assurance).

2. Incremental implementation is necessary for legacy industries

- Wholesale retrofitting of manufacturing systems and existing facilities is costly in terms of capital expenditure and training.

- In agriculture production, where long production cycles offer little room for failure, smaller system changes can de-risk implementation.

- Startups that take time to listen to their clients’ problems may be able to devise smaller scale solutions that consider multiple constraints, with quicker implementation timelines and maintained results.

3. Internal collaboration and communication are as important as tech adoption

- Providing communication channels for front-line workers and production managers to raise issues to leadership not only allows corporates to devise more feasible solutions but gives the workforce agency and buy-in during transformations.

- Testing new innovation solutions alongside the workforce provides a variety of perspectives to better identify the right solution.

- Intermittently assessing goals and milestones with management can help signal the continuation or dissolution of a pilot solution.

- Devising new incentives, compensation structures and celebrating wins can make a big difference in supporting buy-in from the rank-and-file.

4. Manufacturing efficiencies not only provide cost savings, but new business opportunities

- Prospective corporate partners are not always sold on a solution that might only cut costs. However, if a new technology can also unlock capabilities or growth opportunities, executive leadership is more likely to greenlight a pilot project.

- Ingredient and input price hikes mean that “manufacturing teams are tasked with creating more from less. Utilizing byproducts can be a very effective way to do that,” noted Foodbytes’ own Sonia Shekar.

- Waste streams from manufacturing production are finding new uses outside the landfill. In sugar production specifically, waste streams are being converted into biofuel, processed into compost for growers and molded into sustainable packaging.

“One company’s waste really is another company’s valuable ingredient.” — Xinnan Li